State-of-the-art

technology

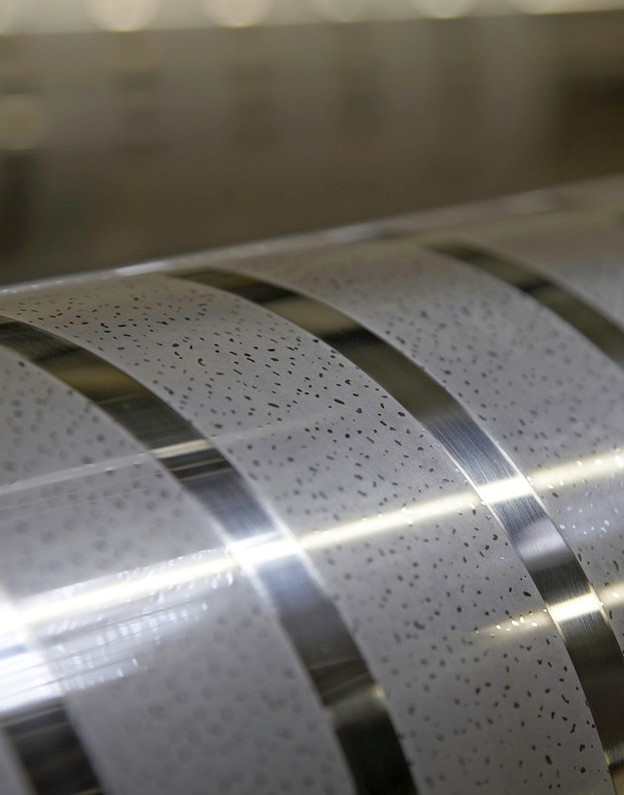

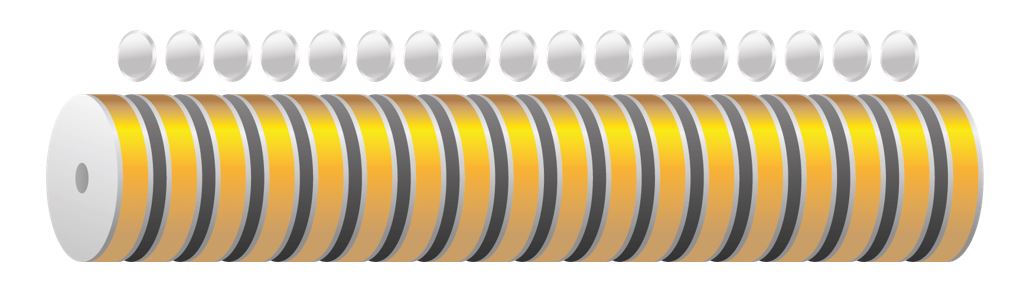

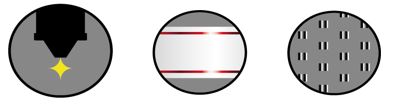

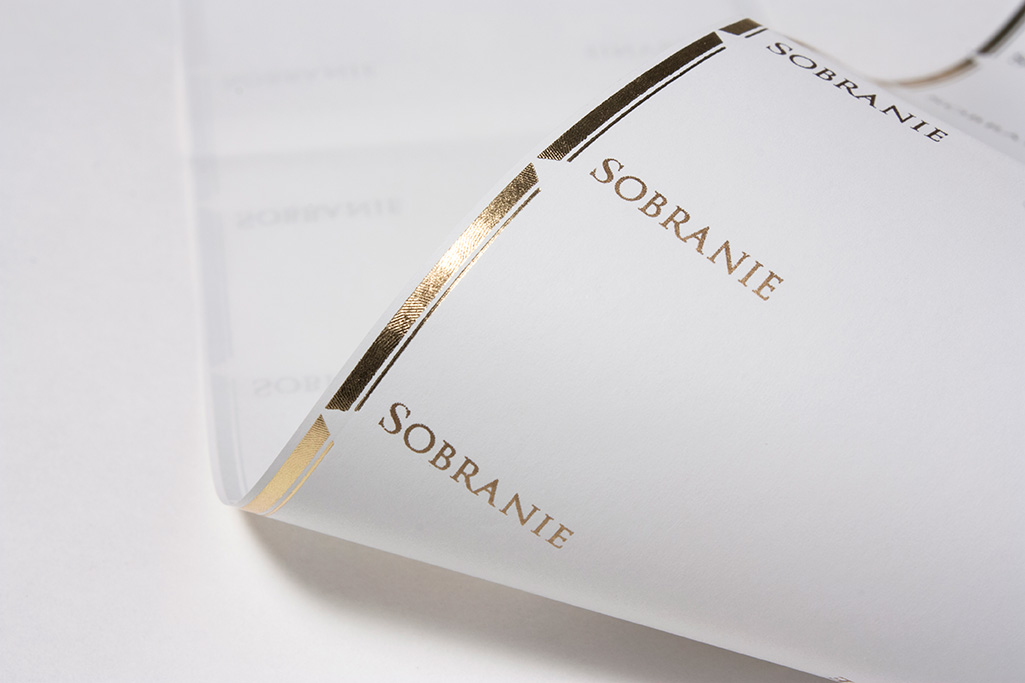

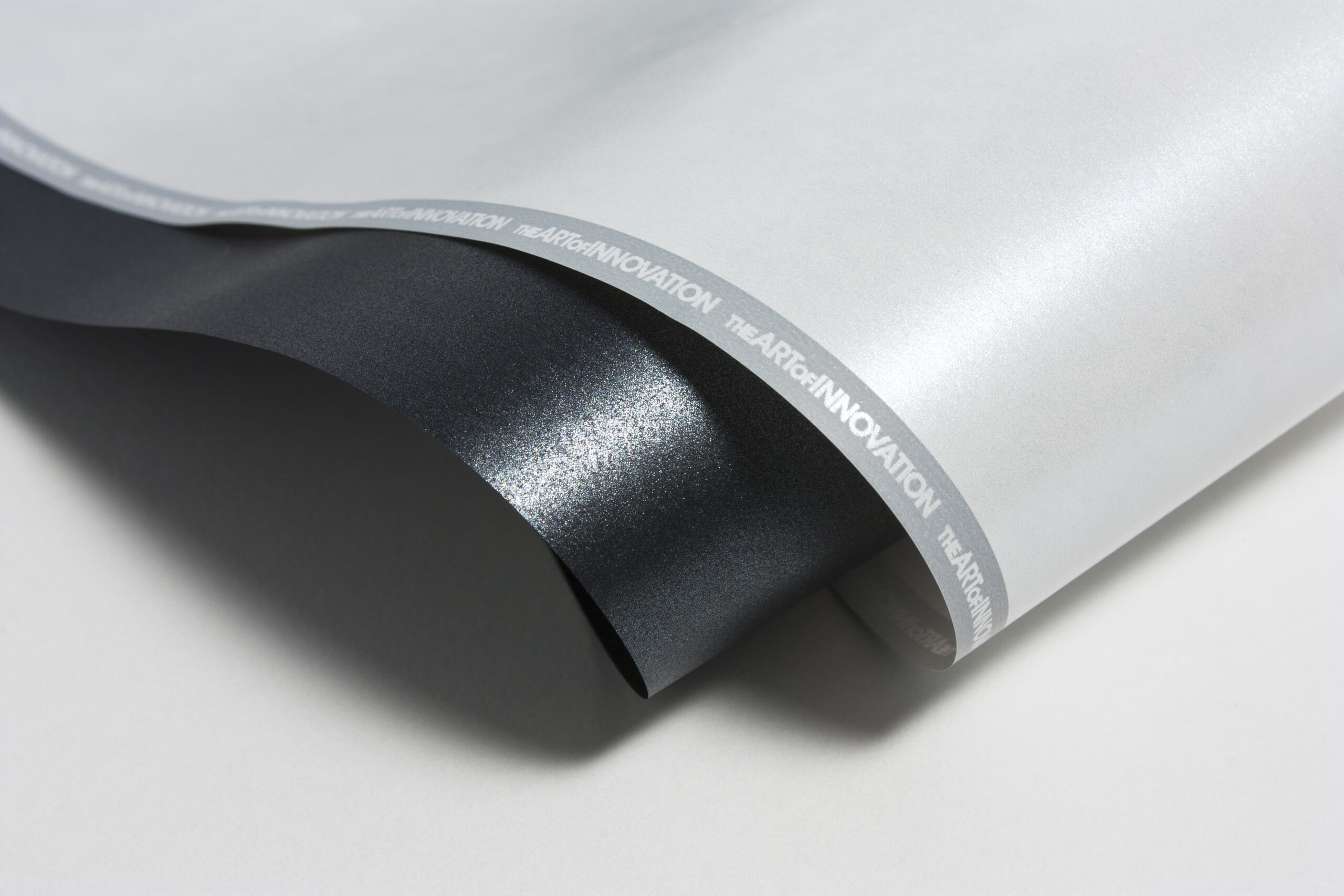

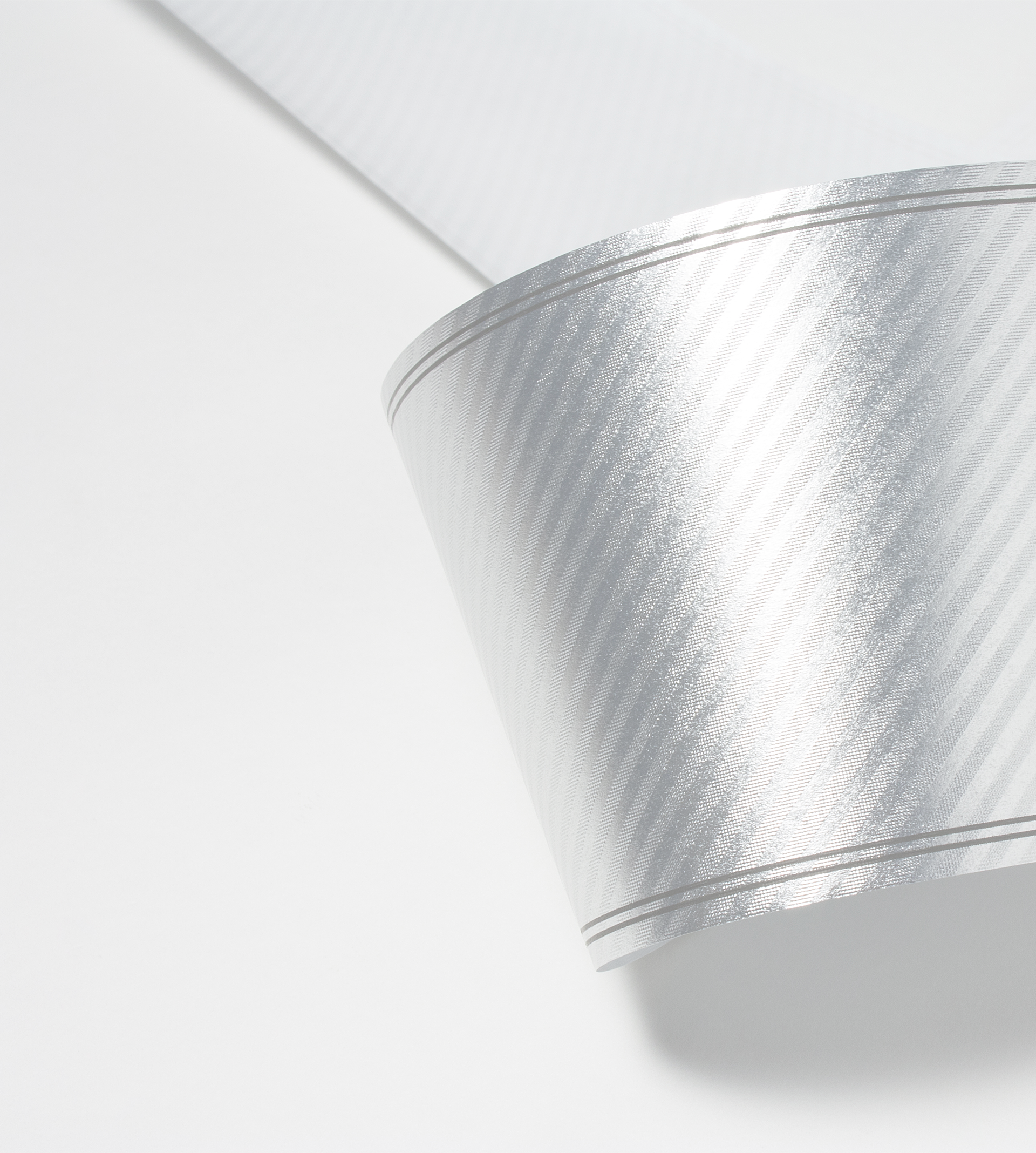

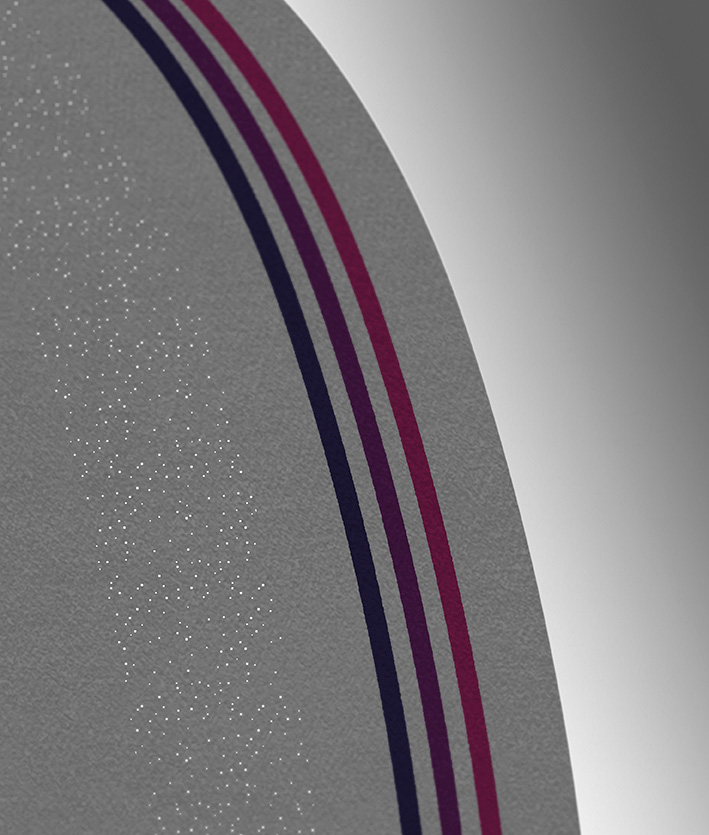

By using modern printing machines, software and automation technologies, we can guarantee the highest quality standards and comprehensive product safety. Our latest printing technologies make it possible to optimize the printing process, minimize errors and maintain the high quality of our products.